Liquid bottle filling devices deliver pharmaceutical producers with a host of significant rewards. To start with, their substantial-speed and exact filling abilities add to a more productive manufacturing system, cutting down manufacturing time and reducing the wastage of precious assets. This streamlined operation not only enhances productiveness but in addition translates to cost personal savings.

The danger Assessment of the selected three important procedures reveals that a large number of challenges are in the inexperienced limit, indicating that the RPN is fewer than 34 (not introduced Within this analyze); consequently, there are no actions or control actions demanded.

By lessening human intervention, they not only minimize errors but also boost aseptic problems, retaining the integrity of pharmaceutical goods.

Why is aseptic stability testing performed? Steadiness screening gives evidence on how the quality of a drug substance or item may differ more than a specified time and beneath the affect of environmental elements like temperature, humidity, and light. All drug goods have to bear balance testing.

The only real approach to manufacture a sterile solution with out terminal sterilization, is to employ an aseptic fill finish course of action that maintains sterility from beginning to finish.

This web page isn't going to exist in your picked language. Your desire was saved and you may be notified once a web page is often seen within your language.

Installed on an array of tube supplies, Quickseal® provides reputable and quick aseptic tube disconnection.

I'm able to revoke my consent click here Anytime with influence for the long run by sending an e-mail to unsubscribe@sartorius.com or by clicking about the "unsubscribe" hyperlink in e-mails I have been given.

Mycap® is designed Along with the identical, established closure program whatever the container or tubing materials. Validate Mycap® after, and use it freely through the complete output approach.

Innovative biomanufacturing procedures need State-of-the-art resources to deliver reliable connections among parts. The Biowelder® TC is an automatic gadget for building sterile connections in between thermoplastic elastomer (TPE) tubing aspects.

Guide filter integrity test shall not be utilized. Filter exam shall be carried out applying machine, and testing results really should be instantly saved and printed. No handbook recording of the result.

Additionally, the automatic nature of liquid bottle filling devices performs an important part in optimizing useful resource allocation and decreasing labor prerequisites. By streamlining the filling method and reducing the necessity for handbook intervention, these machines increase operational performance and productivity.

If FFS equipment are employed for the manufacture of non-sterile products and solutions, FDAs present-day Good Manufacturing Practices (cGMP) specifications ought to be adopted. When utilized to manufacture products meant for subsequent sterilization, these devices may very well be set up in an ecosystem that will Commonly be thought of suitable for the website manufacture and filling of terminally sterilized solutions.

Some time for a full-scale run of your respective beverage will come. But a small-scale run is definitely the optimum financial commitment at this time within your model's development.

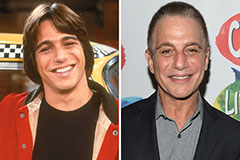

Tony Danza Then & Now!

Tony Danza Then & Now! Alisan Porter Then & Now!

Alisan Porter Then & Now! Mike Vitar Then & Now!

Mike Vitar Then & Now! Christy Canyon Then & Now!

Christy Canyon Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now!